A tree climbing rope is only as good as its termination. Or to put it another way: a splice is the termination that most likely keeps what the rope promises. In contrast to a knot, a splice reduces the breaking strength of a rope only minimally. This is a decisive advantage especially in climbing tree care, where the ropes are exposed to the weather on a daily basis. How is a splice actually made? Why is it better than a knot for the breaking strength?

Strength of a splice: self-locking

A professionally spliced connection of ropes is break-proof and permanently durable. The reason for this is the principle of self-locking. This refers to the resistance caused by static friction between two bodies, which prevents them from slipping or twisting. A rope stretches under tensile load and thereby reduces its diameter. Splicing causes the rope strands to touch each other. The stronger the rope is pulled, the greater the friction force – and the stronger the splice!

Splice vs. knot

In comparison to a knot it becomes obvious how strong a good splice is: A knot reduces the breaking strength of a rope by up to 50 percent. With high-performance fibers such as Dyneema or Vectran, the reduction can be up to 80 percent. An eye splice only reduces the breaking strength by 5 to 15 percent. That’s a tremendous difference.

In addition, the annoying piece of loose rope, which requires a safe knot, is built into the rope during splicing. And of course, a splice is much slimmer – both important points in tree care and tree climbing. The danger of the rope getting caught or stuck is much smaller. Triple advantage: no loose ends, slim connection and more power!

How is a splice made?

Rope construction

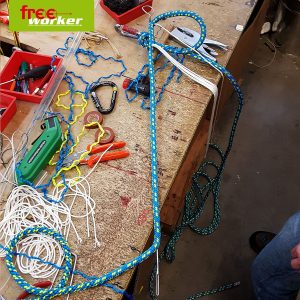

Each splice is based on the specific structure of a rope. Textile ropes, as used for climbing, consist of single, fine fibres or threads, which are bundled to form strands. In an eye splice, for example, the splicer first unravels the end of the rope into its individual strands. By following precise instructions and detailed procedural steps, the splicer interweaves them with himself again after the eye has been formed.

At Freeworker, all splices are also stitched at the end of the splicing process. This sewing secures the splice against slipping and is an indicator for changes in the splice structure.

A splice is made – frame by frame

We make the splice for your work in tree care

We primarily manufacture eye splices, but also, for example, rope shackles for specific rigging operations. We splice in thimbles, rings such as Rigging Rings, pulleys or carabiners according to customer requirements. Our standard model is the short eye splice. We also manufacture eye splices of any size as required. Certified, we splice the tree climbing ropes of the Edelrid XP-e series, the Yale XTC ropes and the Atrax, Black Widow and Lignum by Cousin.

» more information about the Freeworker splices

Repair splice

In case of rope damage, it is possible to work a new splice into the used rope. If possible, the rope should be washed. The rope is no longer spliced with a certificate in this case, because the new manufacturing condition is no longer given.

Tip

For safety reasons we advise against using a climbing rope with two spliced eyes. If you climb to the end of the rope in the direction of the unused end when descending, the splice may shift. We strongly advise you to keep a minimum distance of five meters to the unused eye when tree climbing. In addition, the eye should be checked regularly for shifts or thickening.

More articles on the Freeworker blog

- Splices at Freeworker: We splice what you need

- On a strong line: Tree climbing ropes in tree care

- Clean into the tree: Washing ropes the right way

- 3-way carabiners: Accidental opening

- Freeworker online Product consultation